Edge computing accelerates real-time decision making and supports proactive maintenance

With implementation of Industry 4.0, vibration analysis algorithms supported by cloud server architecture enable easy prediction of potential problems to adopt preventive action. As well, equipment maintenance or replacement can be executed preemptively, significantly enhancing efficiency. ADLINK's innovative equipment status monitoring edge computing platform delivers complete and comprehensive data acquisition, analysis, and upload. The real-time analytics can be sent to the data center, by upload to the cloud and fast connection to the ERP/MES upper layer application system. Effective dynamic preventive maintenance strategies can be generated according to machine operation status in real-time, improving equipment reliability.

Simple, Speedy Deployment

Unlike conventional combination-based solutions, ADLINK’s MCM-100 adopts an integrated design, providing complete data acquisition, highly accurate real-time analysis and data upload, along with connection to information database, for complete equipment status monitoring and analysis. Deployment in the environment is significantly streamlined, reducing development time.

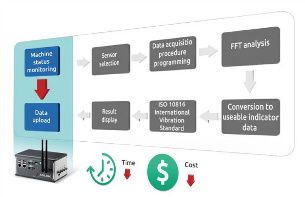

Solution Diagram

A machine condition monitoring edge platform ideally suited for data acquisition and vibration measurement applications. Delivering 24-hour vibration monitoring for rotating machinery and equipment.

![]() Seamless interconnection

Seamless interconnection![]() Automatic event alarm notices

Automatic event alarm notices.jpg)

Features

Fast, Simple Whole-System Setup with No Downtime

Integrated

function in compact construction Built-in IEPE 2mA excitation current source, requires no additional signal conditioning

Complete One-Operation Data Acquisition, Analysis, and Upload

Delivers edge-based data acquisition, domain algorithm, data analytics capability, converting machine status, usage trends,alarms, and more for distribution

Smart Factory Predictive Maintenance

Factory/Equipment management Alarm notification Historical data Viewable at mobile end Lifting equipment, vacuum pumps, air compressors and other rotating machines are critical in a wide variety of manufacturing and processing operations. Any suspension of production due to machine error can represent prohibitive losses inrevenue. ADLINK’s Smart equipment status monitoring solution improves dramatically on conventional manual monitoring methods, supporting 24-hour online monitoring and malfunction prediction such that precise control of equipment status can be achieved and real-time feedback maintenance provided.

.png)